How To Tig Weld: Which Is Harder - Stainless or Aluminum TIG?

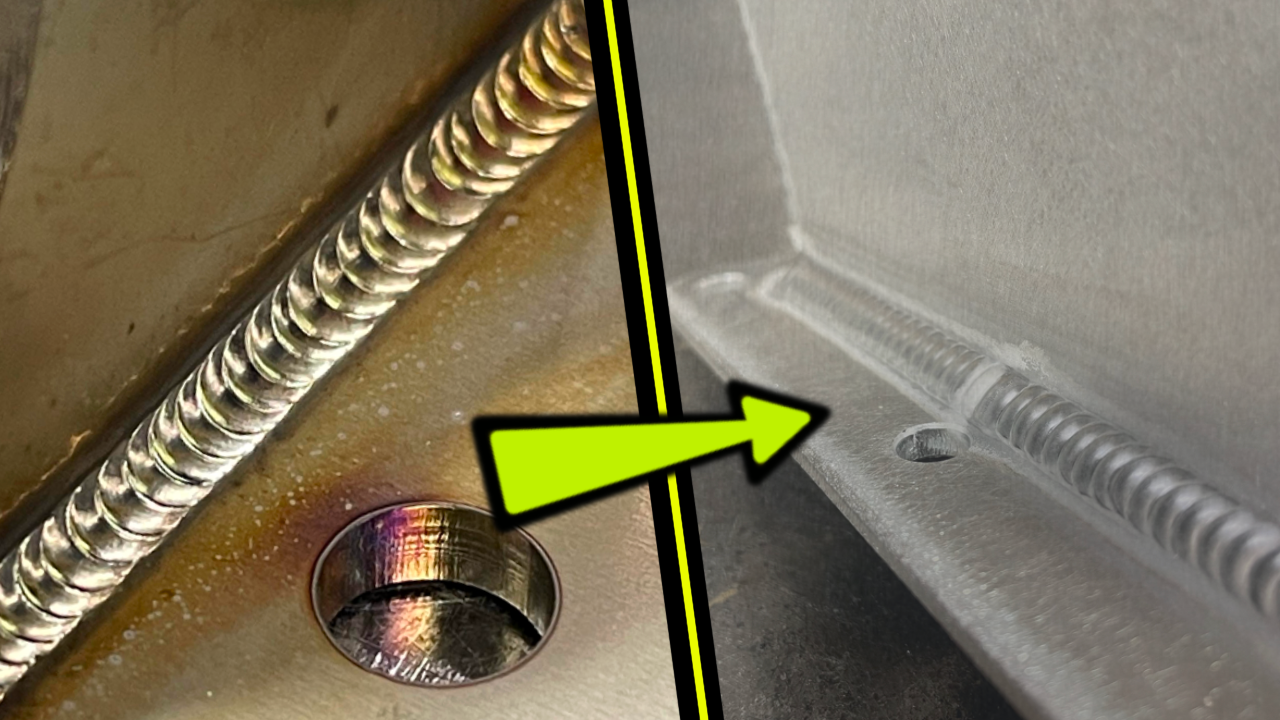

Stainless vs Aluminum TIG Welding: Which Is Harder?

One of the biggest questions I get as a welding instructor and content creator is simple: what’s harder, TIG welding stainless steel or aluminum?

I’ve worked with both metals for years, from my own projects to teaching students through my online programs. The truth is, both stainless steel TIG and aluminum TIG welding bring their own headaches. Each metal has quirks that can trip you up, no matter how experienced you are.

Let’s break it down into four categories: heat control, puddle stability, finish, and forgiveness factor and see which one really takes the crown for being the most difficult.

Heat Control

When it comes to heat control, aluminum TIG welding tends to give welders the biggest shock. The reason? Aluminum doesn’t glow red hot as it heats up. Its melting point is around 660°C (1220°F), much lower than stainless steel at about 1500°C (2750°F).

With stainless TIG, you can see the metal start to glow when it gets too hot. That warning sign lets you back off the pedal or add more filler rod before it’s too late. Aluminum gives you no such warning — everything looks fine one second, then suddenly it collapses into a molten puddle.

For this category, aluminum TIG wins for being the most unforgiving.

Puddle Stability

On the flip side, aluminum puddles are usually more stable. As long as your torch is set up cleanly and your angle is steady, the puddle tends to stay where you put it.

Stainless steel is another story. Even with perfect prep, expensive gear, and years of experience, the puddle can start acting up out of nowhere. One dab of filler and suddenly the bead is wandering like it’s your first day holding a torch. This is especially true when running passes around coped pipe, puddle control becomes a constant battle.

In this case, stainless steel TIG takes the point for being harder.

Finish

Let’s talk about the final look. With aluminum, once your setup is dialed in, you can usually get shiny, clean results straight away. No polish, no tricks, just bright welds that look solid.

Stainless TIG welding is where frustration really sets in. Even when you think you’ve run the perfect bead, you flip your hood up to find a dull, grey mess. Achieving that gold-coin stack look takes a delicate balance of heat, speed, filler rod, and gas coverage. Get one variable slightly wrong, and it all falls apart.

Here, stainless steel TIG is clearly the tougher challenge.

Forgiveness Factor

Finally, let’s look at forgiveness. If you lay down a bead you’re not happy with, stainless TIG gives you some room to fix it. You can often re-pass a weld without filler and make it passable, at least cosmetically.

Aluminum TIG doesn’t give you that option. Try to re-pass without filler and the bead just blobs together, looking worse than before. Adding filler can fix it, but it also makes the weld wider and more obvious.

So for forgiveness, aluminum TIG is the more difficult one.

The Verdict

That brings us to a tie: aluminum is tougher for heat control and forgiveness, while stainless is more challenging for puddle stability and finish.

Both metals have their own set of challenges, and every welder will have a different opinion depending on their experience. For beginners and even experienced welders, the key is practice, patience, and learning how each material behaves under the torch.

👉 Check out the full video breakdown on my YouTube channel here: Watch The Lesson

Cheers!

Dusty

Download your exclusive Beginner's Guide to Aluminum TIG Welding!

Enter your information below to receive exclusive PDF mini-textbook straight to your email.

We hate SPAM. We will never sell your information, for any reason.