TIG Welding Mistakes to Avoid!

Avoid These Common Beginner Mistakes in TIG Welding

When you’re just getting started with TIG welding, it’s real easy to make things harder than they need to be. I’ve been there too—overthinking everything, overheating passes, and wondering why nothing looks the way it should.

So if you're feeling stuck, frustrated, or just not confident in your welds yet—this article is for you.

Let’s talk through the biggest beginner mistakes I see, and more importantly, how to fix them. These are the same things I cover in my programs, and they make a huge difference in the kind of results you’ll start seeing.

1. Bad Posture and Setup

I say it all the time—your setup matters. If you’re hunched over or wrestling your torch hand the whole time, your weld is going to suffer. You need to be stable and comfortable. Get your piece positioned at a good angle so you can see the puddle clearly and move smooth from start to finish.

Welding is a lot easier when you're not fighting your body.

Quick fix: Tilt your workpiece toward you slightly. This way the welding pass will point towards you on a bit of an angle. This will allow you to see as you are welding more 'towards' yourself, instead of across the line of sight you're looking at it from. Use small blocks of scrap metal, or a fixture to lift the piece off the table slightly, you'll be able to see so much better. Elevating your workpiece even an inch or so makes a HUGE difference in comfort, as well as visibility. Position your head near the end of the joint, not the middle. You’ll see the whole weld path much better, and in combination with these other couple of tips it's going to make a MASSIVE difference.

2. Wrong Amperage Setup

I see this constantly. People ask me, “Dusty, what settings should I use?” Truth is—it depends. Every joint, every thickness, every machine is different. But one thing’s always true: it’s better to set your amps slightly high and control them with a foot pedal.

If you start too low, your arc won’t even get the puddle going. You’ll end up with cold-looking welds and bad fusion. I’d rather have the option to back off than not be able to bring the heat when I need it.

Rule of thumb: Set it 10–15 amps higher than what you think you’ll need. Then learn to ride the pedal and watch the puddle.

3. Waiting Too Long to Add Filler

This one kills welds fast. You light up and stare at the puddle too long, waiting for the “perfect” moment. But by then, it’s already too hot and the base metal starts to melt away.

Instead—dab in filler early. I call it Fill and Chill. That first dab helps regulate the heat and gives the arc something to grab onto. It’s a heat sink and a stabilizer all in one.

Try this: Arc on, quick two dabs of filler, pause and chill. Then watch as the filler settles down and the puddle will stabilize. Trust me—this will save your starts.

4. Arc Length Too Long

Keep your tungsten in close. Like, really close.

If your arc is jumping all over the place, or your puddle is wide and unstable, chances are your arc length is too long. That messes with heat control and gas coverage.

Get in tight, steady your hand, and keep the arc sharp. Don’t be afraid to rest your hand on the bench or use a finger glide to stabilize.

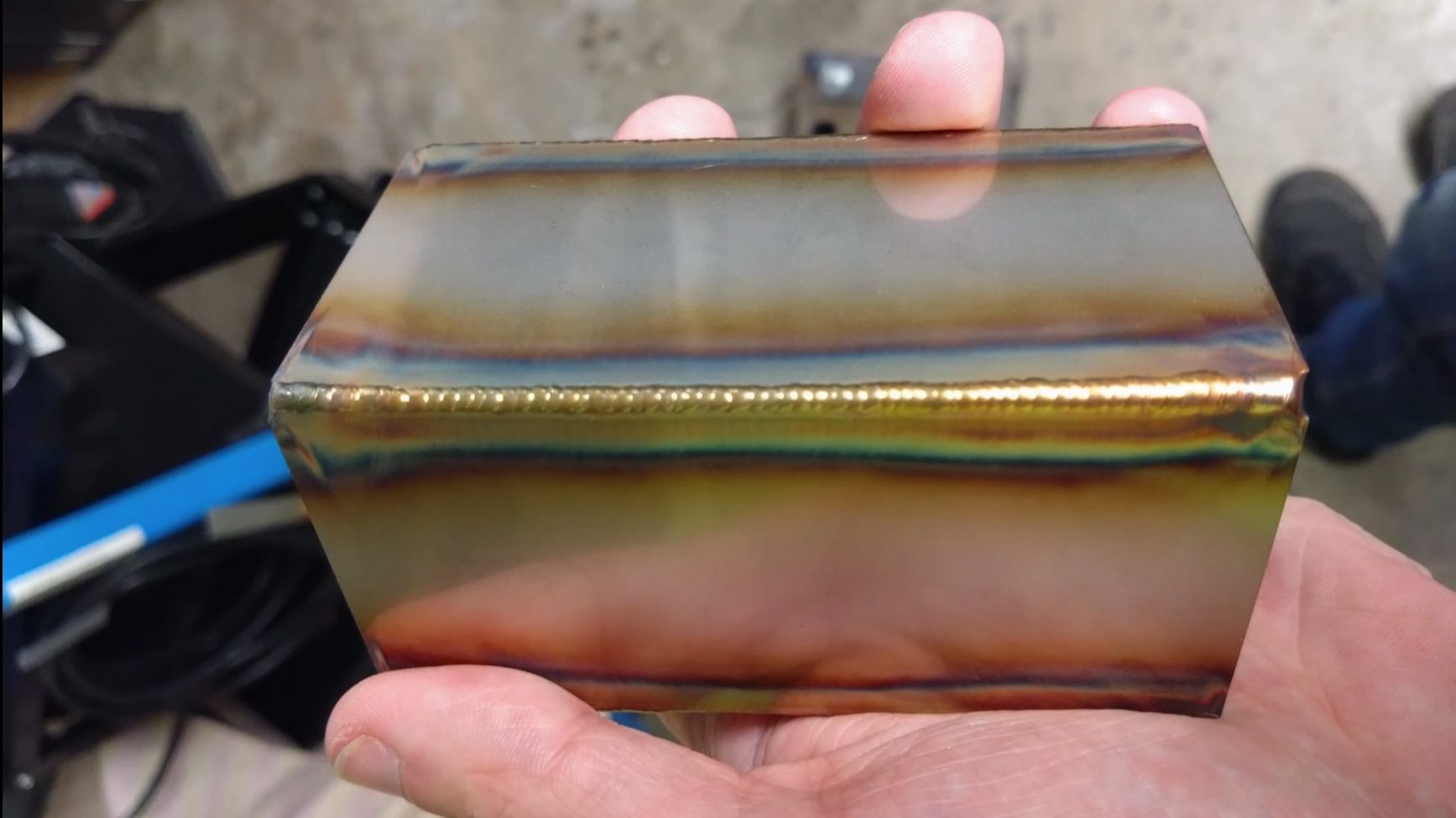

5. Inadequate Post Flow

Stainless or other types of steel welds turning gray and crusty? You probably moved your torch away too soon after the weld is finished.

When your weld is still glowing, it’s still vulnerable. Let that post flow finish completely before pulling away. It protects the weld, the tungsten, and your filler tip too.

Pro tip: Stay still. Wait until the red glow fades completely, then give it 2-3 more seconds before moving. And keep that filler rod in the gas envelope while you’re at it.

Want to Watch Me Do It?

I cover all of this—and show exactly how I do it—in this Lesson:

👉 Avoiding Common Beginner Mistakes in TIG Welding

You’ll see me run through everything step by step. If you’re struggling to keep your welds consistent or clean, go watch that and follow along.

And if you’re ready to really dial things in, check out my online TIG programs. They’ve helped thousands of welders around the world—from beginners to folks brushing up on skills they haven’t used in years.

There’s no guesswork. No fluff. Just real TIG welding instruction, built from two decades of experience.

Thanks for reading—and go lay down a clean bead today.

My name’s Dusty. Fill and chill.

Download your exclusive Beginner's Guide to Aluminum TIG Welding!

Enter your information below to receive exclusive PDF mini-textbook straight to your email.

We hate SPAM. We will never sell your information, for any reason.