TIG Welding Aluminum Without Burn-Through: My Filler Rod Secret

Burn-through sucks. Especially when you're welding aluminum. You’re trying to get a clean, smooth weld—and bam—you blow a hole right through it. Yeah, I’ve been there too.

But here’s the deal: there’s one simple thing that can make all the difference. The filler rod.

If you know how to use your filler rod right, it becomes your secret weapon for controlling heat and stopping burn-through before it even starts.

Let me break it down for you.

Why Burn-Through Happens (Especially on Aluminum)

Aluminum’s a different beast. It’s super thermally conductive, which means heat travels FAST through it. That’s great for cooking pans—terrible for TIG welding. You hit it with too much heat, and it just melts away on you, and it's almost impossible to recover it at that point. Especially at the end of a weld when everything’s mega hot.

So, how do you stop that from happening?

Enter: The Filler Rod

Now listen, your filler rod isn’t just for stacking dimes or building up the pass. It's one of the best tools you’ve got to control heat (before it gets out of control.) Every time you dab filler into the puddle, it helps absorb some of that heat and keep things under control.

It's like throwing a cold sponge into a hot pan. If you can mediate the heat before it becomes excessive, Boom—instant temperature drop.

My Go-To Move: “Fill and Chill”

Step 1: Light up the arc.

Step 2: Throw in a couple of dabs of filler right away.

Step 3: Pause. Chill. Let that filler stabilize the puddle.

This is what my saying "Fill and Chill" refers to.

Now you’re not starting cold—you’ve got some meat and potatoes in the joint and the heat isn’t going wild on you. You can start good and hot and not have to worry about burning through- Game changer.

Use a Bigger Rod (Trust Me)

I get this question all the time: “What size filler rod should I use?”

I love 1/8" (3.2mm) rod for aluminum. A lot of folks try to go smaller, like 3/32", but that just doesn’t suck up the heat the same way. With a bigger rod, you’re adding more mass with each dab, and that’s what helps you keep burn-through in check.

Too hot? Dab more. Need more control? Slow down and keep feeding. That filler is your heat sink. I'll switch to a 3/32" (2.4mm) filler rod if I'm working with really thin stuff like anything around 1/16" (1.6mm) but for most other thicknesses, I'm rocking ol' trusty 1/8" rod.

Real Talk: Don’t Be Scared to Start

I see this all the time—someone’s scared to start the weld. They light up, but they wait too long to add filler. By then, the puddle’s already screaming hot and the base metal is on the verge of collapse.

Be bold. Light up, dab-dab, pause, then roll into it. If your start is clean, the rest of your weld will flow better every single time.

“It Still Looks Too Hot…”

Alright, if you’re still feeling like it’s getting too hot too quick—even with filler—check these:

-

Travel speed – You might be moving too slow. Keep it steady.

-

Torch angle – Stay around 15–20° to direct heat where you want it.

-

Amperage – Try backing off just a little. Or ease the pedal back if you’ve got one.

-

Material thickness – If you’re welding super thin stuff, it’ll always be more sensitive. That’s where this filler technique really shines. Make sure your puddle doesn't get too wide, and keep it filled up.

Machine Setup Basics

If you’re not sure where to set your machine for aluminum TIG:

-

Amperage: For 1/8" aluminum, start around 120–130 amps. Foot pedal is your best friend here.

-

AC Balance: Start around 70–75% EN (electrode negative) for solid cleaning and penetration.

-

Post Flow: Keep your tungsten clean! 8–10 seconds will usually do it.

-

Shielding Gas: 100% argon. No mixes. No compromise.

Need a machine recommendation? I’ve had solid results with Everlast and Canaweld units—especially for folks not looking to spend $5K on a machine.

Want to See It in Action?

I cover all this—and show you exactly how I do it—in this training video:

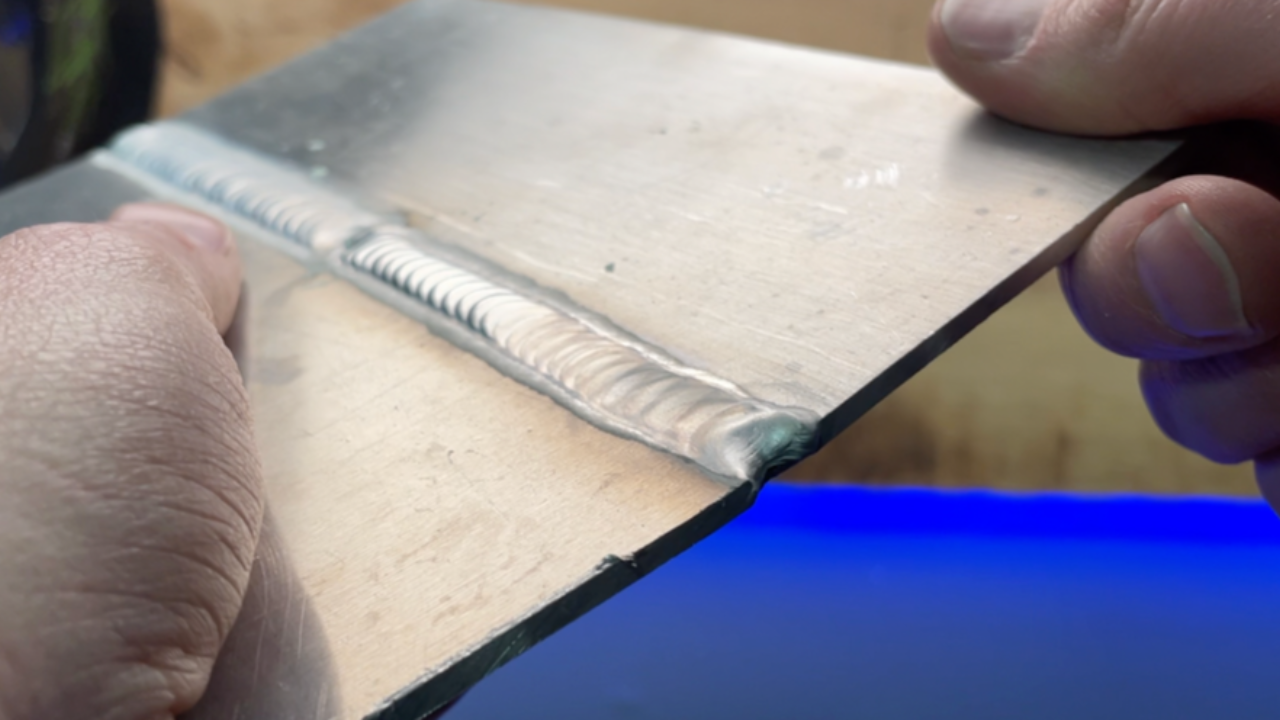

👉 How to TIG Weld Aluminum Without Burn-Through

Seriously, watch how I start every weld. You’ll see that quick dab of filler right at the beginning. That’s Fill and Chill in real life.

A Few Bonus Tips

-

Clean the metal. Aluminum oxides are no joke. Use a dedicated stainless steel brush and wipe it down with acetone.

-

Use a foot pedal. If you’re new, just having that ability to throttle the heat in real time is a game-changer.

-

Practice on scrap. Run starts over and over until they feel second nature.

-

Pulse if needed. Pulse settings can help control heat too, but don’t overcomplicate things right out of the gate.

Wrapping It Up

If you’re burning through aluminum—this is your fix:

-

Bigger filler rod (1/8" is ideal)

-

Fill and Chill method every single time

- Make sure your puddle width stays in control and doesn't get too wide.

-

Stay calm, start strong, and adjust your rhythm

Welding aluminum isn’t easy—but it doesn’t have to be miserable either. Master the filler rod, and you’ll be stacking dimes without blowing holes.

You got this.

And hey—do a random act of kindness for a stranger today.

My name’s Dusty. Fill and chill. We’ll talk soon. Peace.

Download your exclusive Beginner's Guide to Aluminum TIG Welding!

Enter your information below to receive exclusive PDF mini-textbook straight to your email.

We hate SPAM. We will never sell your information, for any reason.