Why Is My TIG Weld Cracking? - How to TIG Weld Aluminum

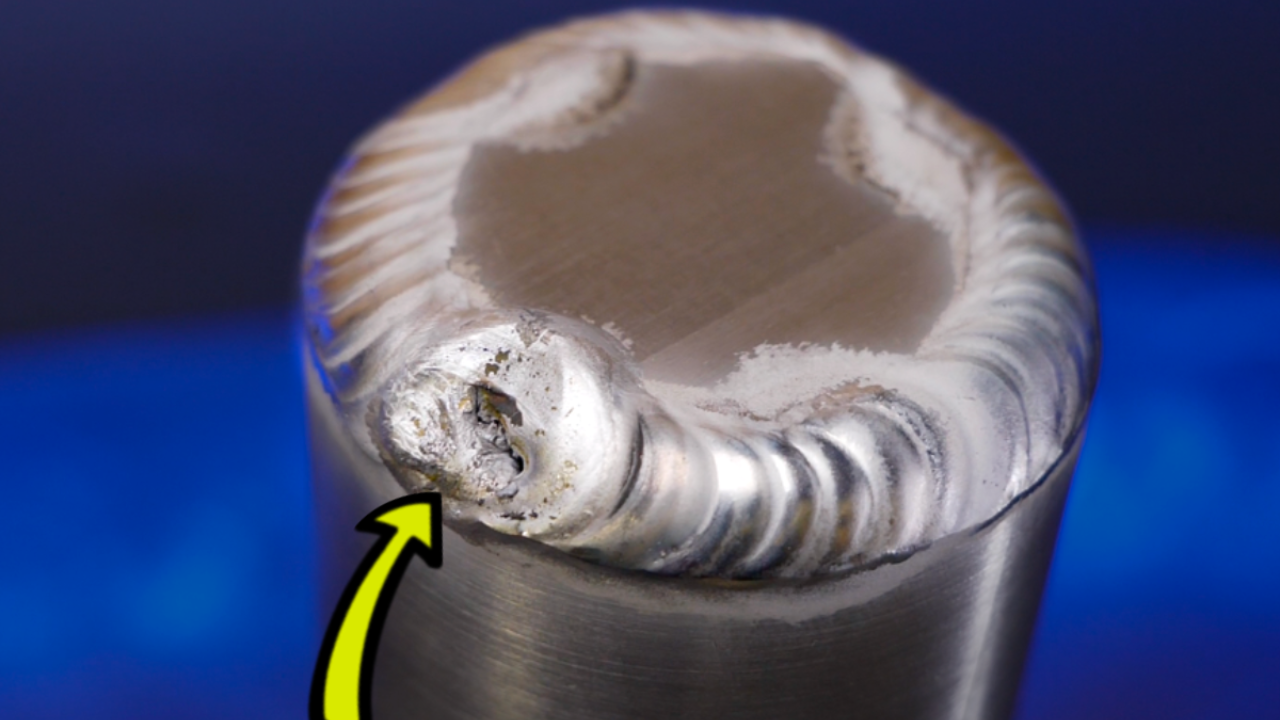

Why Is My TIG Weld Cracking?

Weld cracking is one of the most frustrating issues to deal with in TIG welding. You’re doing everything right (or at least you think you are) and yet you still end up with cracks along the weld or heat-affected zone. Let’s break down the real reasons your TIG welds might be cracking and how to fix them.

1. Wrong Filler Rod

Using the wrong filler for the base metal is one of the most common causes of cracking. Different metals expand and cool at different rates. If your filler isn’t matched properly, you’ll get cracking either right after welding (hot cracking) or later during use (cold cracking).

Fix it: Double-check that your filler matches your base metal, especially when welding dissimilar materials like 304 stainless to mild steel or aluminum alloys.

2. Poor Fit-Up or Joint Design

Too much gap between parts or an awkward joint design will pull your weld apart under stress. Cracking can also happen at the start or stop of a weld if the heat distribution isn’t controlled.

Fix it: Aim for tight fit-ups and proper edge prep. If you’re doing edge welds or butt joints on thin materials, make sure you’ve got good control of torch angle and amperage.

3. Contaminated Base Metal

Cracking often comes from dirty metal: oil, paint, rust, mill scale, or even fingerprint oils can cause issues. TIG is clean welding, and it demands clean material.

Fix it: Use a dedicated stainless wire brush, wipe with acetone, and make sure your gloves are clean before touching the joint area.

4. Too Much Heat Input

If you’re blasting a thin section with 120 amps and no chill, you’re probably setting up for cracks. Overheating leads to grain growth in the weld zone and weakens it.

Fix it: Dial in your amps for the metal thickness and use pulse if possible. A smaller, tighter arc helps reduce unnecessary heat input.

5. No Preheat (When You Should Be Preheating)

On certain metals like tool steels or even thick aluminum, skipping preheat can lead to massive stress between the hot and cold zones. This stress = cracks.

Fix it: Learn which materials require a preheat and follow a basic inter-pass temp routine. It doesn’t have to be fancy...just consistent.

6. Bad Gas Coverage

TIG needs 100% argon flow with good torch technique. Poor shielding leads to oxidation and brittle welds. You might not see it until the weld cracks under stress.

Fix it: Check for gas leaks, keep your cup size appropriate (bigger for stainless or outside corners), and be mindful of wind if welding outdoors.

7. Welding the Wrong Type of Metal Without Realizing It

This one trips up a lot of people. You think you’re welding mild steel, but it’s got a high carbon content or some weird alloy mix, and your weld just keeps cracking no matter what you do.

Fix it: When in doubt, spark test, grind, or even get a metal analysis. Guessing can cost you hours of frustration.

Conclusion:

If cracking’s been killing your confidence, you’re not alone! The good news is that it’s fixable. A few key tweaks to your prep, technique, and settings can completely change the outcome. If you want a faster way to figure it all out, I break it down step-by-step inside My Programs. When you're ready, I’ll be there to help you weld better, faster.

Dusty.

Download your exclusive Beginner's Guide to Aluminum TIG Welding!

Enter your information below to receive exclusive PDF mini-textbook straight to your email.

We hate SPAM. We will never sell your information, for any reason.