High Level TIG Welding Practice

If you've ever stared at a basic practice plate and thought, "There’s gotta be more I can do with this," you're absolutely right. In this blog, I’m going to walk you through a TIG welding exercise that levels up your skills fast. We’re talking joint prep, heat control, tacking strategies, and pro-level arc management—all using simple TIG welding coupons.

The Setup: Start With Precision

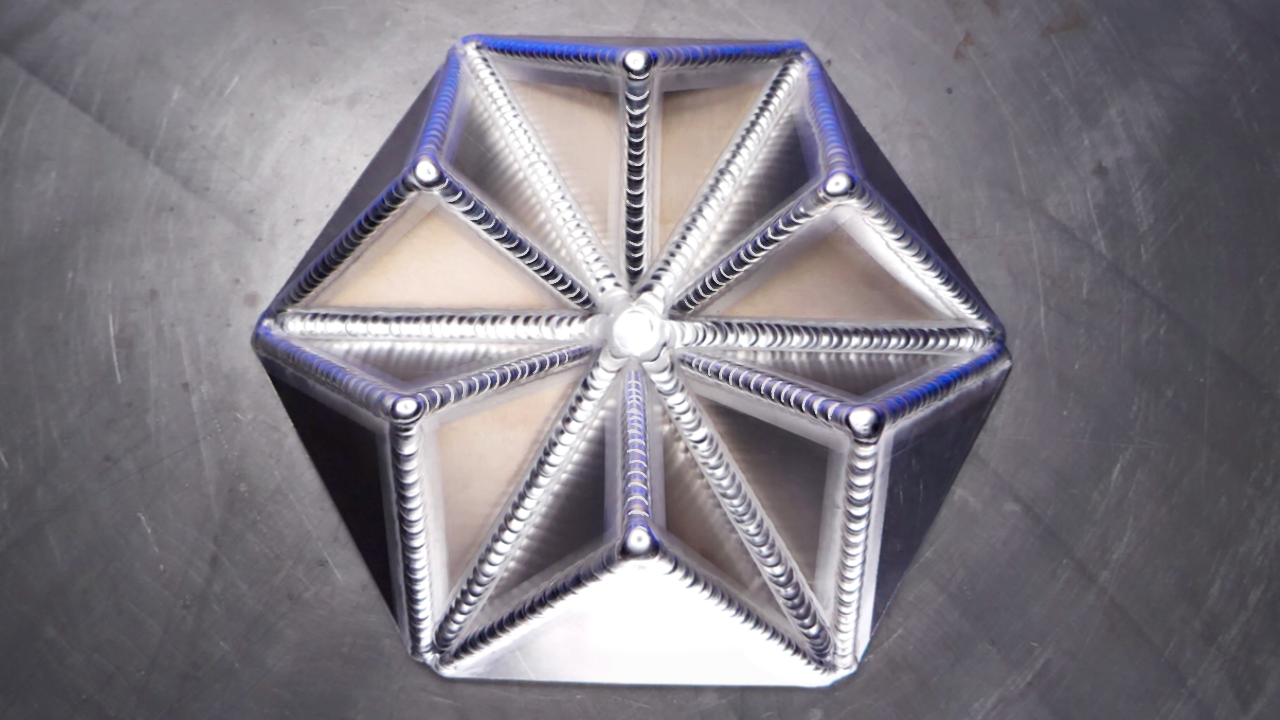

This all starts with a single flat aluminum coupon. We divide it into equal squares, cut diagonally to create 18 clean triangles (ok you'll need one extra piece from another coupon,) and prep every single piece. Precision cutting and edge prep matter. If your triangles aren’t accurate, you’ll spend your weld time fighting gaps and misalignment.

If you want to see this all demonstrated in a full lesson, Watch The Full Video Here

Once cut, sand each piece flat and deburr the edges. Clean them thoroughly with acetone. Then—and this is a pro move—use a ruler to wire brush only the joint edges that will be welded. Don’t guess. Study your final design first, then prep exactly what’s needed.

Tack Like a Pro

Next, we tack our project with intention. Put tacks near the ends of your passes, not in the middle of passes where your welding will have a bump to go over later. Tack small, tack clean. And if gaps appear, don’t force it—skim material off multiple pieces evenly for a tight final fit.

The Weld Plan: Direction & Symmetry

Before striking an arc, map your entire weld sequence. Start with the outer corner joints—they heat up the fastest. Bounce around the project to spread heat evenly and avoid distortion. Then tackle your center joints and finish with the fillet welds, always welding from edge to center.

Plan your filler dabs to land clean buttons in symmetrical spots. Think of every weld like it’s on display—because it is.

Machine Settings Matter

For this exercise, I used the Everlast 230 Typhoon. The frequency is turned up to keep the arc cone tight. Balance is dialed in for a clean tip and good cleaning—skip the pulse settings and focus on technique. Ride the pedal, manage the heat, and watch how your filler material matches your amperage.

Final Results: Professional Practice

Every pass is smooth, clean, and shows solid penetration. Even the small version of this project presents challenges that sharpen your skillset fast. This isn’t about finishing a pretty cube—it’s about stacking real-world TIG welding habits into your muscle memory.

Want to see it all in action? 👉 Watch The Full Video Here

If this project got your gears turning, go download the free workbooks or check out my full online TIG programs. These aren’t just courses—they’re real-world systems to help you get cleaner, stronger welds with every pass.

Fill and chill.

—Dusty

Download your exclusive Beginner's Guide to Aluminum TIG Welding!

Enter your information below to receive exclusive PDF mini-textbook straight to your email.

We hate SPAM. We will never sell your information, for any reason.